CONVEYOR PRODUCTS PTY LTD are the exclusive Australian distributor for STARK Vulcanizing Products in The Netherlands, who are the worldwide leaders in high quality, best performing conveyor belt vulcanizer on the market today.

STARK VULCANIZING PRESSES are light weight, durable and versa- tile with complete availability of coverage for all splice lengths, fabric ply or steel cord.

Our presses are easy to set-up and operate and easy to maintain. Stark Vulcanizing Presses are made of high-grade aluminium platens and beams to provide maximum tensile and bending strength with minimum weight. All Stark Vulcanizing Presses provide uniform temperature of high and pressure required to vulcanize a wide array of conveyor belts. We manufacture to all sizes and have a stock of the more traditional sizes used in the industry.

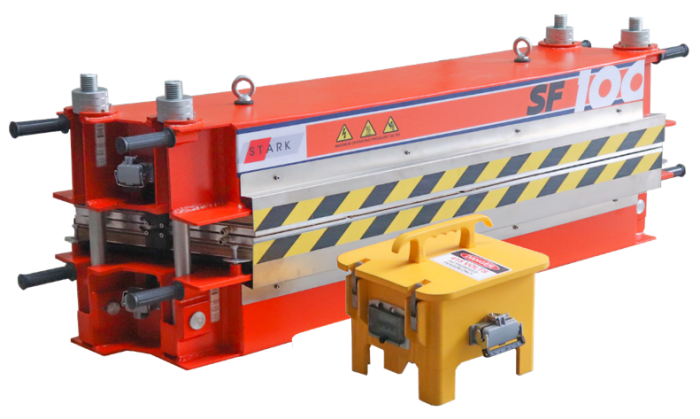

STARK SECTIONAL VULCANIZER

- Lightweight compact design for easy transport

- Includes flush valves and inset bolts/nuts connecting the traverse bars

- All electrical systems are CE, CSA and UL approved

- Durable for use in harshest of environments

- Pressure bolts pass through the cross-beam profile for a high level of safety

- Exact temperature regulation via an electronic control box

- Even pressure distribution across the splice area

- Vulcanizing temperature is uniform and accurate

- Automatic features for setting the temperature and curing time

- Standard sizes are available (custom size upon request)

STARK FRAME STYLE VULCANIZER

- Platen: Utilizes innovative flexible platen constructed from extruded plank, silicone heating element and durable composite insulation. Each platen contours to the belt’s irregularities, ensuring uniform results. Maximum temperature 163°C

- Frame: Two light and rugged aluminium frames comprise upper and lower portions of press. Ends equipped with carrying handles on smaller models.

- Pressure/Cooling: Pressure bag ensures uniform pressure across splice surface. Quick cooling by channeling water through extruded platen.

STARK LIGHT DUTY VULCANIZER

- Platen: Utilizes innovative flexible platen constructed from extruded plank, silicone heating element and durable composite insulation. Each platen contours to the belt’s irregularities, ensuring uniform results. Maximum temperature 185°C

- Frame: Two light and rugged aluminium frames comprise upper and lower portions of press. Ends equipped with carrying handles on smaller models.

- Pressure / Cooling: Pressure bag ensures uniform pressure across splice surface. Quick cooling by channeling water through extruded platen.

STARK SUPERSPOTTER

- 300mm Square water cooled vulcanising platens

- Silicone rubber heating element with fast heat up

- Stark pressure bag ensures uniform pressure

- Welded aluminium C- Frame with easy handling

- Thermostatic control panel which is CE approved

- Maximum operative pressure of 75 P.S.I